抗弯刚度概念及其计算方法范文

本作品内容为抗弯刚度概念及其计算方法范文,格式为 docx ,大小 92591 KB ,页数为 9页

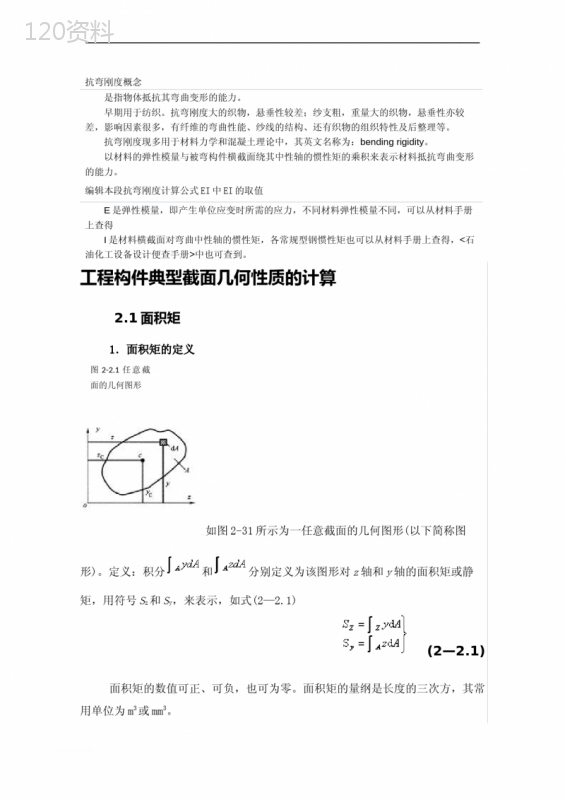

('抗弯刚度概念是指物体抵抗其弯曲变形的能力。早期用于纺织。抗弯刚度大的织物,悬垂性较差;纱支粗,重量大的织物,悬垂性亦较差,影响因素很多,有纤维的弯曲性能、纱线的结构、还有织物的组织特性及后整理等。抗弯刚度现多用于材料力学和混凝土理论中,其英文名称为:bendingrigidity。以材料的弹性模量与被弯构件横截面绕其中性轴的惯性矩的乘积来表示材料抵抗弯曲变形的能力。编辑本段抗弯刚度计算公式EI中EI的取值E是弹性模量,即产生单位应变时所需的应力,不同材料弹性模量不同,可以从材料手册上查得I是材料横截面对弯曲中性轴的惯性矩,各常规型钢惯性矩也可以从材料手册上查得,<石油化工设备设计便查手册>中也可查到。工程构件典型截面几何性质的计算2.1面积矩1.面积矩的定义图2-2.1任意截面的几何图形如图2-31所示为一任意截面的几何图形(以下简称图形)。定义:积分和分别定义为该图形对z轴和y轴的面积矩或静矩,用符号Sz和Sy,来表示,如式(2—2.1)(2—2.1)面积矩的数值可正、可负,也可为零。面积矩的量纲是长度的三次方,其常用单位为m3或mm3。肃清流毒影响获得了辉煌的成就,通过参观学习,认识到了为什么会有腐败案例,知道了要铭记初心,不断的提高自我素质Ellipticityofelbowpipeswithdiameterslessthanorequalto150mmmustbenotgreaterthan8%diameterof200mmorlessshallnotbegreaterthan6%.Wallthicknessofthepipewallthinningratemustnotexceedtheoriginal15%.Creaseroughness:diameter125mmorless,shallnotexceed3mmdiameterlessthanorequalto200mm,notmorethan4mm.7.3.9simmeringbendingproductionofsquaresteeltubeextension,tousethewholetubebending.Interfaceifnecessary,theweldingpositionshouldbelocatedinthemiddleoftheverticalarm.7.3.10installexpansionjointsshouldbedone.Ifdesignisnotrequired,pipecompensatorlengthenshouldconformtotherequirementsinthefollowingtable:squarescalelengthδxisequalto1/2.Prestretchtolerance:casing+5mm,+10mm.7.3.11pipeform,location,spacingshallmeetthedesignandspecifications.7.3.12pipingonbackorreturnpipeathigherlevelsoftheuppertoautomaticvalvetoinstalladrainvalvebelowthehorizontalparts.7.3.13supportsandhangersofchecksandthenumber1)hangerinstalledmustbecheckedbeforeinstallationofsupportsandhangerspartmodels,specificationsofspringssettingvalues,whetherthematerialsmeettherequirementsofdrawingsanddocuments;2)supportsandhangersofmaterial,sizeandaccuracyshallconformtotheprovisionsofthedesigndrawings,materialtechnicalrequirementsshouldbeconsistentwithnationalstandards,industrystandardsandtechnicalrequirementsrelatedtothealloyspectrumreviewshouldbecarriedout;3)pipesupportsandhangerspartplantproductqualitycertificateforeachvariablespringsupports,constantsupporthangers,dampers,damperfunction,thereshouldbefactorycalibratedtest2.面积矩与形心平面图形的形心坐标公式如式(2—2.2)(2—2.2)或改写成,如式(2—2.3)(2—2.3)面积矩的几何意义:图形的形心相对于指定的坐标轴之间距离的远近程度。图形形心相对于某一坐标距离愈远,对该轴的面积矩绝对值愈大。图形对通过其形心的轴的面积矩等于零;反之,图形对某一轴的面积矩等于零,该轴一定通过图形形心。3.组合截面面积矩和形心的计算组合截面对某一轴的面积矩等于其各简单图形对该轴面积矩的代数和。如式(2—2.4)(2—2.4)式中,A和yi、zi分别代表各简单图形的面积和形心坐标。组合平面图形的形心位置由式(2—2.5)确定。(2—2.5)2.2极惯性矩、惯性矩和惯性积1.极惯性矩肃清流毒影响获得了辉煌的成就,通过参观学习,认识到了为什么会有腐败案例,知道了要铭记初心,不断的提高自我素质Ellipticityofelbowpipeswithdiameterslessthanorequalto150mmmustbenotgreaterthan8%diameterof200mmorlessshallnotbegreaterthan6%.Wallthicknessofthepipewallthinningratemustnotexceedtheoriginal15%.Creaseroughness:diameter125mmorless,shallnotexceed3mmdiameterlessthanorequalto200mm,notmorethan4mm.7.3.9simmeringbendingproductionofsquaresteeltubeextension,tousethewholetubebending.Interfaceifnecessary,theweldingpositionshouldbelocatedinthemiddleoftheverticalarm.7.3.10installexpansionjointsshouldbedone.Ifdesignisnotrequired,pipecompensatorlengthenshouldconformtotherequirementsinthefollowingtable:squarescalelengthδxisequalto1/2.Prestretchtolerance:casing+5mm,+10mm.7.3.11pipeform,location,spacingshallmeetthedesignandspecifications.7.3.12pipingonbackorreturnpipeathigherlevelsoftheuppertoautomaticvalvetoinstalladrainvalvebelowthehorizontalparts.7.3.13supportsandhangersofchecksandthenumber1)hangerinstalledmustbecheckedbeforeinstallationofsupportsandhangerspartmodels,specificationsofspringssettingvalues,whetherthematerialsmeettherequirementsofdrawingsanddocuments;2)supportsandhangersofmaterial,sizeandaccuracyshallconformtotheprovisionsofthedesigndrawings,materialtechnicalrequirementsshouldbeconsistentwithnationalstandards,industrystandardsandtechnicalrequirementsrelatedtothealloyspectrumreviewshouldbecarriedout;3)pipesupportsandhangerspartplantproductqualitycertificateforeachvariablespringsupports,constantsupporthangers,dampers,damperfunction,thereshouldbefactorycalibratedtest任意平面图形如图2-31所示,其面积为A。定义:积分称为图形对O点的极惯性矩,用符号IP,表示,如式(2—2.6)(2—2.6)极惯性矩是相对于指定的点而言的,即同一图形对不同的点的极惯性矩一般是不同的。极惯性矩恒为正,其量纲是长度的4次方,常用单位为m4或mm4。(1)圆截面对其圆心的极惯性矩,如式(2—7)(2—2.7)(2)对于外径为D、内径为d的空心圆截面对圆心的极惯性矩,如式(2—2.8)(2—2.8)式中,d/D为空心圆截面内、外径的比值。2.惯性矩在如图6-1所示中,定义积分,如式(2—2.9)(2—2.9)称为图形对z轴和y轴的惯性矩。惯性矩是对一定的轴而言的,同一图形对不同的轴的惯性矩一般不同。惯性矩恒为正值,其量纲和单位与极惯性矩相同。同一图形对一对正交轴的惯性矩和对坐标原点的极惯性矩存在着一定的关系。如式2—2.10)IP=Iz+Iy(2—2.10)上式表明,图形对任一点的极惯性矩,等于图形对通过此点且在其平面内的任一对正交轴惯性矩之和。表6-1给出了一些常见截面图形的面积、形心和惯性矩计算公式,以便查用。工程中使用的型钢截面,如工字钢、槽钢、角钢等,这些截面的几何性质可肃清流毒影响获得了辉煌的成就,通过参观学习,认识到了为什么会有腐败案例,知道了要铭记初心,不断的提高自我素质Ellipticityofelbowpipeswithdiameterslessthanorequalto150mmmustbenotgreaterthan8%diameterof200mmorlessshallnotbegreaterthan6%.Wallthicknessofthepipewallthinningratemustnotexceedtheoriginal15%.Creaseroughness:diameter125mmorless,shallnotexceed3mmdiameterlessthanorequalto200mm,notmorethan4mm.7.3.9simmeringbendingproductionofsquaresteeltubeextension,tousethewholetubebending.Interfaceifnecessary,theweldingpositionshouldbelocatedinthemiddleoftheverticalarm.7.3.10installexpansionjointsshouldbedone.Ifdesignisnotrequired,pipecompensatorlengthenshouldconformtotherequirementsinthefollowingtable:squarescalelengthδxisequalto1/2.Prestretchtolerance:casing+5mm,+10mm.7.3.11pipeform,location,spacingshallmeetthedesignandspecifications.7.3.12pipingonbackorreturnpipeathigherlevelsoftheuppertoautomaticvalvetoinstalladrainvalvebelowthehorizontalparts.7.3.13supportsandhangersofchecksandthenumber1)hangerinstalledmustbecheckedbeforeinstallationofsupportsandhangerspartmodels,specificationsofspringssettingvalues,whetherthematerialsmeettherequirementsofdrawingsanddocuments;2)supportsandhangersofmaterial,sizeandaccuracyshallconformtotheprovisionsofthedesigndrawings,materialtechnicalrequirementsshouldbeconsistentwithnationalstandards,industrystandardsandtechnicalrequirementsrelatedtothealloyspectrumreviewshouldbecarriedout;3)pipesupportsandhangerspartplantproductqualitycertificateforeachvariablespringsupports,constantsupporthangers,dampers,damperfunction,thereshouldbefactorycalibratedtest从附录的型钢表中查取。3.惯性积如图2—32所示,积分定义为图形对y,、z轴的惯性积,用符号Iyz表示,如式(2—11)(2—11)图2-2.2具有轴对称的图形惯性积是对于一定的一对正交坐标轴而言的,即同一图形对不同的正交坐标轴的惯性积不同,惯性积的数值可正、可负、可为零,其量纲和单位与惯性矩相同。由惯性积的定义可以得出如下结论:若图形具有对称轴,则图形对包含此对称轴在内的一对正交坐标抽的惯性积为零。如图2-32所示,y为图形的对称轴.则整个图形对y、z轴的惯,性积等于零。常见图形的面积、形心和惯性矩表2—2.1序号图形面积形心位置惯性矩(形心轴)1肃清流毒影响获得了辉煌的成就,通过参观学习,认识到了为什么会有腐败案例,知道了要铭记初心,不断的提高自我素质Ellipticityofelbowpipeswithdiameterslessthanorequalto150mmmustbenotgreaterthan8%diameterof200mmorlessshallnotbegreaterthan6%.Wallthicknessofthepipewallthinningratemustnotexceedtheoriginal15%.Creaseroughness:diameter125mmorless,shallnotexceed3mmdiameterlessthanorequalto200mm,notmorethan4mm.7.3.9simmeringbendingproductionofsquaresteeltubeextension,tousethewholetubebending.Interfaceifnecessary,theweldingpositionshouldbelocatedinthemiddleoftheverticalarm.7.3.10installexpansionjointsshouldbedone.Ifdesignisnotrequired,pipecompensatorlengthenshouldconformtotherequirementsinthefollowingtable:squarescalelengthδxisequalto1/2.Prestretchtolerance:casing+5mm,+10mm.7.3.11pipeform,location,spacingshallmeetthedesignandspecifications.7.3.12pipingonbackorreturnpipeathigherlevelsoftheuppertoautomaticvalvetoinstalladrainvalvebelowthehorizontalparts.7.3.13supportsandhangersofchecksandthenumber1)hangerinstalledmustbecheckedbeforeinstallationofsupportsandhangerspartmodels,specificationsofspringssettingvalues,whetherthematerialsmeettherequirementsofdrawingsanddocuments;2)supportsandhangersofmaterial,sizeandaccuracyshallconformtotheprovisionsofthedesigndrawings,materialtechnicalrequirementsshouldbeconsistentwithnationalstandards,industrystandardsandtechnicalrequirementsrelatedtothealloyspectrumreviewshouldbecarriedout;3)pipesupportsandhangerspartplantproductqualitycertificateforeachvariablespringsupports,constantsupporthangers,dampers,damperfunction,thereshouldbefactorycalibratedtest234562.3组合截面的惯性矩肃清流毒影响获得了辉煌的成就,通过参观学习,认识到了为什么会有腐败案例,知道了要铭记初心,不断的提高自我素质Ellipticityofelbowpipeswithdiameterslessthanorequalto150mmmustbenotgreaterthan8%diameterof200mmorlessshallnotbegreaterthan6%.Wallthicknessofthepipewallthinningratemustnotexceedtheoriginal15%.Creaseroughness:diameter125mmorless,shallnotexceed3mmdiameterlessthanorequalto200mm,notmorethan4mm.7.3.9simmeringbendingproductionofsquaresteeltubeextension,tousethewholetubebending.Interfaceifnecessary,theweldingpositionshouldbelocatedinthemiddleoftheverticalarm.7.3.10installexpansionjointsshouldbedone.Ifdesignisnotrequired,pipecompensatorlengthenshouldconformtotherequirementsinthefollowingtable:squarescalelengthδxisequalto1/2.Prestretchtolerance:casing+5mm,+10mm.7.3.11pipeform,location,spacingshallmeetthedesignandspecifications.7.3.12pipingonbackorreturnpipeathigherlevelsoftheuppertoautomaticvalvetoinstalladrainvalvebelowthehorizontalparts.7.3.13supportsandhangersofchecksandthenumber1)hangerinstalledmustbecheckedbeforeinstallationofsupportsandhangerspartmodels,specificationsofspringssettingvalues,whetherthematerialsmeettherequirementsofdrawingsanddocuments;2)supportsandhangersofmaterial,sizeandaccuracyshallconformtotheprovisionsofthedesigndrawings,materialtechnicalrequirementsshouldbeconsistentwithnationalstandards,industrystandardsandtechnicalrequirementsrelatedtothealloyspectrumreviewshouldbecarriedout;3)pipesupportsandhangerspartplantproductqualitycertificateforeachvariablespringsupports,constantsupporthangers,dampers,damperfunction,thereshouldbefactorycalibratedtest1.惯性矩和惯性积的平行移轴公式任意平面图形如图2-33所示。z、y为一对正交的形心轴,z1、y1为与形心轴平行的另一对正交轴,平行轴间的距离分别为a和b。已知图形对形心轴的惯性矩Iz、Iy和惯性积Izy,现求图形对z1、y1轴的惯肃清流毒影响获得了辉煌的成就,通过参观学习,认识到了为什么会有腐败案例,知道了要铭记初心,不断的提高自我素质Ellipticityofelbowpipeswithdiameterslessthanorequalto150mmmustbenotgreaterthan8%diameterof200mmorlessshallnotbegreaterthan6%.Wallthicknessofthepipewallthinningratemustnotexceedtheoriginal15%.Creaseroughness:diameter125mmorless,shallnotexceed3mmdiameterlessthanorequalto200mm,notmorethan4mm.7.3.9simmeringbendingproductionofsquaresteeltubeextension,tousethewholetubebending.Interfaceifnecessary,theweldingpositionshouldbelocatedinthemiddleoftheverticalarm.7.3.10installexpansionjointsshouldbedone.Ifdesignisnotrequired,pipecompensatorlengthenshouldconformtotherequirementsinthefollowingtable:squarescalelengthδxisequalto1/2.Prestretchtolerance:casing+5mm,+10mm.7.3.11pipeform,location,spacingshallmeetthedesignandspecifications.7.3.12pipingonbackorreturnpipeathigherlevelsoftheuppertoautomaticvalvetoinstalladrainvalvebelowthehorizontalparts.7.3.13supportsandhangersofchecksandthenumber1)hangerinstalledmustbecheckedbeforeinstallationofsupportsandhangerspartmodels,specificationsofspringssettingvalues,whetherthematerialsmeettherequirementsofdrawingsanddocuments;2)supportsandhangersofmaterial,sizeandaccuracyshallconformtotheprovisionsofthedesigndrawings,materialtechnicalrequirementsshouldbeconsistentwithnationalstandards,industrystandardsandtechnicalrequirementsrelatedtothealloyspectrumreviewshouldbecarriedout;3)pipesupportsandhangerspartplantproductqualitycertificateforeachvariablespringsupports,constantsupporthangers,dampers,damperfunction,thereshouldbefactorycalibratedtest性矩Iz1、Iy1和惯性积Iz1y1。有惯性矩和惯性积的平行移轴公式如式(2—2.12)和式(2—2.13)(2—2.12)Iz1y1=Izy+abA(2—2.13)可见,图形对于形心轴的惯性矩是对所有平行轴的惯性矩中最小的一个。在应用平行移轴公式(2—2.12)时,要注意应用条件,即y、z轴必须是通过形心的轴,且z1、y1轴必须分别与z、y轴平行。在应用式(2—2.13)计算惯性积时,还须注意a、b的正负号,它们是截面形心c在z1oy1坐标系中的坐标值。2.组合截合惯性矩计算组合图形对某一轴的惯性矩,等于其各组成部分简单图形对该轴惯性矩之和,如式(2—2.14)肃清流毒影响获得了辉煌的成就,通过参观学习,认识到了为什么会有腐败案例,知道了要铭记初心,不断的提高自我素质Ellipticityofelbowpipeswithdiameterslessthanorequalto150mmmustbenotgreaterthan8%diameterof200mmorlessshallnotbegreaterthan6%.Wallthicknessofthepipewallthinningratemustnotexceedtheoriginal15%.Creaseroughness:diameter125mmorless,shallnotexceed3mmdiameterlessthanorequalto200mm,notmorethan4mm.7.3.9simmeringbendingproductionofsquaresteeltubeextension,tousethewholetubebending.Interfaceifnecessary,theweldingpositionshouldbelocatedinthemiddleoftheverticalarm.7.3.10installexpansionjointsshouldbedone.Ifdesignisnotrequired,pipecompensatorlengthenshouldconformtotherequirementsinthefollowingtable:squarescalelengthδxisequalto1/2.Prestretchtolerance:casing+5mm,+10mm.7.3.11pipeform,location,spacingshallmeetthedesignandspecifications.7.3.12pipingonbackorreturnpipeathigherlevelsoftheuppertoautomaticvalvetoinstalladrainvalvebelowthehorizontalparts.7.3.13supportsandhangersofchecksandthenumber1)hangerinstalledmustbecheckedbeforeinstallationofsupportsandhangerspartmodels,specificationsofspringssettingvalues,whetherthematerialsmeettherequirementsofdrawingsanddocuments;2)supportsandhangersofmaterial,sizeandaccuracyshallconformtotheprovisionsofthedesigndrawings,materialtechnicalrequirementsshouldbeconsistentwithnationalstandards,industrystandardsandtechnicalrequirementsrelatedtothealloyspectrumreviewshouldbecarriedout;3)pipesupportsandhangerspartplantproductqualitycertificateforeachvariablespringsupports,constantsupporthangers,dampers,damperfunction,thereshouldbefactorycalibratedtest(2—2.14)在计算组合图形对z、y轴的惯性矩时,应先将组合图形分成若干个简单图形,并计算出每一简单图形对平行于z、y轴的自身形心轴的惯性矩,然后利用平行移轴公式(2—2.12)计算出各简单图形对z、y轴的惯性矩,最后利用式(2—2.14)求总和。2.4主惯性轴和主惯性矩过图形上任一点都可得到一对主轴,通过截面图形形心的主惯性轴,称为形心主轴,图形对形心主轴的惯性矩称为形心主惯性矩。在对构件进行强度、刚度和稳定计算中,常常需要确定形心主轴和计算形心主惯性矩。因此,确定形心主轴的位置是十分重要的。由于图形对包括其对称轴在内的一对正交坐标轴的惯性积为零,所以对于如图6-4所示具有对称轴的截面图形,可根据图形具有对称轴的情况,观察确定形心主轴的位置。(1)如果图形有一根对称轴,则此轴必定是形心主轴、而另一根形心主轴通过形心,并与对称轴垂直,如图2-34b)、d)所示。(2)如果图形有两根对称轴,则该两轴都为形心主轴,如图6-4a)、c)所示。(3)如果图形具有3根或更多根对称轴,过图形形心的任何轴都是形心主、轴,且图形对其任一形心主轴的惯性矩都相等,如图6-4e)、f)所示。图2-2.4具有对称轴的截面图形肃清流毒影响获得了辉煌的成就,通过参观学习,认识到了为什么会有腐败案例,知道了要铭记初心,不断的提高自我素质Ellipticityofelbowpipeswithdiameterslessthanorequalto150mmmustbenotgreaterthan8%diameterof200mmorlessshallnotbegreaterthan6%.Wallthicknessofthepipewallthinningratemustnotexceedtheoriginal15%.Creaseroughness:diameter125mmorless,shallnotexceed3mmdiameterlessthanorequalto200mm,notmorethan4mm.7.3.9simmeringbendingproductionofsquaresteeltubeextension,tousethewholetubebending.Interfaceifnecessary,theweldingpositionshouldbelocatedinthemiddleoftheverticalarm.7.3.10installexpansionjointsshouldbedone.Ifdesignisnotrequired,pipecompensatorlengthenshouldconformtotherequirementsinthefollowingtable:squarescalelengthδxisequalto1/2.Prestretchtolerance:casing+5mm,+10mm.7.3.11pipeform,location,spacingshallmeetthedesignandspecifications.7.3.12pipingonbackorreturnpipeathigherlevelsoftheuppertoautomaticvalvetoinstalladrainvalvebelowthehorizontalparts.7.3.13supportsandhangersofchecksandthenumber1)hangerinstalledmustbecheckedbeforeinstallationofsupportsandhangerspartmodels,specificationsofspringssettingvalues,whetherthematerialsmeettherequirementsofdrawingsanddocuments;2)supportsandhangersofmaterial,sizeandaccuracyshallconformtotheprovisionsofthedesigndrawings,materialtechnicalrequirementsshouldbeconsistentwithnationalstandards,industrystandardsandtechnicalrequirementsrelatedtothealloyspectrumreviewshouldbecarriedout;3)pipesupportsandhangerspartplantproductqualitycertificateforeachvariablespringsupports,constantsupporthangers,dampers,damperfunction,thereshouldbefactorycalibratedtest抗弯截面系数在横截面上离中性轴最远的各点处,弯曲正应力最大,其值为比值Iz/ymax仅与截面的形状与尺寸有关,称为抗弯截面系数,并用Wz表示,即Wz=Iz/ymax由公式可见,最大弯曲正应力与弯矩成正比,与抗弯截面系数成反比。抗弯截面系数Wz综合反映了横截面的形状与尺寸对弯曲正应力的影响。一些常用抗弯截面系数肃清流毒影响获得了辉煌的成就,通过参观学习,认识到了为什么会有腐败案例,知道了要铭记初心,不断的提高自我素质Ellipticityofelbowpipeswithdiameterslessthanorequalto150mmmustbenotgreaterthan8%diameterof200mmorlessshallnotbegreaterthan6%.Wallthicknessofthepipewallthinningratemustnotexceedtheoriginal15%.Creaseroughness:diameter125mmorless,shallnotexceed3mmdiameterlessthanorequalto200mm,notmorethan4mm.7.3.9simmeringbendingproductionofsquaresteeltubeextension,tousethewholetubebending.Interfaceifnecessary,theweldingpositionshouldbelocatedinthemiddleoftheverticalarm.7.3.10installexpansionjointsshouldbedone.Ifdesignisnotrequired,pipecompensatorlengthenshouldconformtotherequirementsinthefollowingtable:squarescalelengthδxisequalto1/2.Prestretchtolerance:casing+5mm,+10mm.7.3.11pipeform,location,spacingshallmeetthedesignandspecifications.7.3.12pipingonbackorreturnpipeathigherlevelsoftheuppertoautomaticvalvetoinstalladrainvalvebelowthehorizontalparts.7.3.13supportsandhangersofchecksandthenumber1)hangerinstalledmustbecheckedbeforeinstallationofsupportsandhangerspartmodels,specificationsofspringssettingvalues,whetherthematerialsmeettherequirementsofdrawingsanddocuments;2)supportsandhangersofmaterial,sizeandaccuracyshallconformtotheprovisionsofthedesigndrawings,materialtechnicalrequirementsshouldbeconsistentwithnationalstandards,industrystandardsandtechnicalrequirementsrelatedtothealloyspectrumreviewshouldbecarriedout;3)pipesupportsandhangerspartplantproductqualitycertificateforeachvariablespringsupports,constantsupporthangers,dampers,damperfunction,thereshouldbefactorycalibratedtest',)

提供抗弯刚度概念及其计算方法范文会员下载,编号:1700742278,格式为 docx,文件大小为9页,请使用软件:wps,office word 进行编辑,PPT模板中文字,图片,动画效果均可修改,PPT模板下载后图片无水印,更多精品PPT素材下载尽在某某PPT网。所有作品均是用户自行上传分享并拥有版权或使用权,仅供网友学习交流,未经上传用户书面授权,请勿作他用。若您的权利被侵害,请联系963098962@qq.com进行删除处理。

下载

下载 下载

下载 下载

下载 下载

下载 下载

下载 下载

下载 下载

下载 下载

下载 下载

下载 下载

下载 下载

下载 下载

下载