项目部封样间管理制度,项目部管理制度大全

本作品内容为项目部封样间管理制度,格式为 doc ,大小 62976 KB ,页数为 4页

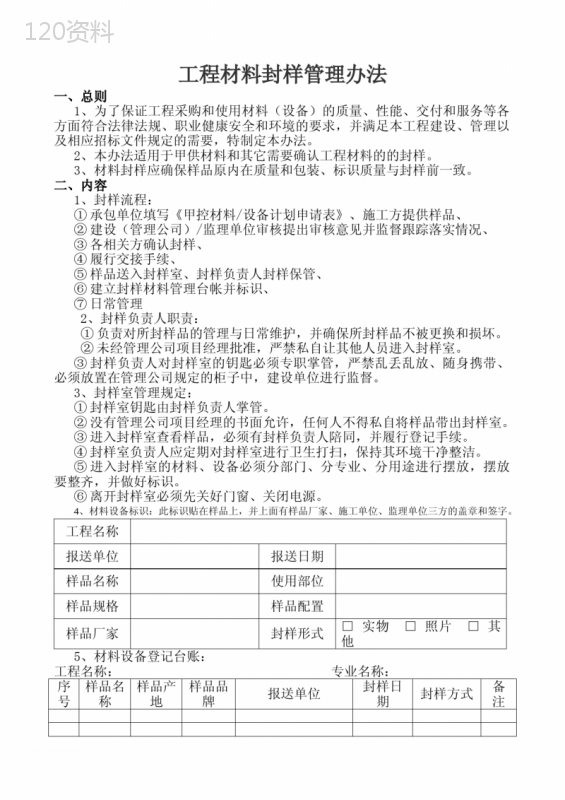

("工程材料封样管理办法一、总则1、为了保证工程采购和使用材料(设备)的质量、性能、交付和服务等各方面符合法律法规、职业健康安全和环境的要求,并满足本工程建设、管理以及相应招标文件规定的需要,特制定本办法。2、本办法适用于甲供材料和其它需要确认工程材料的的封样。3、材料封样应确保样品原内在质量和包装、标识质量与封样前一致。二、内容1、封样流程:①承包单位填写《甲控材料/设备计划申请表》、施工方提供样品、②建设(管理公司)/监理单位审核提出审核意见并监督跟踪落实情况、③各相关方确认封样、④履行交接手续、⑤样品送入封样室、封样负责人封样保管、⑥建立封样材料管理台帐并标识、⑦日常管理2、封样负责人职责:①负责对所封样品的管理与日常维护,并确保所封样品不被更换和损坏。②未经管理公司项目经理批准,严禁私自让其他人员进入封样室。③封样负责人对封样室的钥匙必须专职掌管,严禁乱丢乱放、随身携带、必须放置在管理公司规定的柜子中,建设单位进行监督。3、封样室管理规定:①封样室钥匙由封样负责人掌管。②没有管理公司项目经理的书面允许,任何人不得私自将样品带出封样室。③进入封样室查看样品,必须有封样负责人陪同,并履行登记手续。④封样室负责人应定期对封样室进行卫生打扫,保持其环境干净整洁。⑤进入封样室的材料、设备必须分部门、分专业、分用途进行摆放,摆放要整齐,并做好标识。⑥离开封样室必须先关好门窗、关闭电源。4、材料设备标识:此标识贴在样品上,并上面有样品厂家、施工单位、监理单位三方的盖章和签字。工程名称报送单位报送日期样品名称使用部位样品规格样品配置样品厂家封样形式□实物□照片□其他5、材料设备登记台账:工程名称:专业名称:序号样品名称样品产地样品品牌报送单位封样日期封样方式备注地形平坦开阔,地层由第四系全新冲积层,第四系上更新统冲层组成,局部表覆第四系全新统人工堆积层。第四系全新统冲积层厚度约25~50m,岩性主要为黏土、粉质黏土、粉土、粉砂、细砂;第四系上更新统冲积层厚度大于50m,岩性主要为黏性土、粉土、粉细砂等。管桩深度范围内地层主要为:粉土、黏土、粉质黏土,局部表层为杂填土。couplingCentreshallbechecked,thesecondpouredconcretestrengthofmorethan70%.Intheprocessofreamingorboring,apartfromthespecialprovisionsinfactory,doesnotallowanyworkthatmayaffectthecouplingCentre,suchasirrigation,tocylinderconnectionstofloodthecondenserpipesandsoon.Wellboring,hingeboltholeflangewithcouplingofvertical,notoblique.Mountingboltsshouldbeaddedlubricants,typinggentlywithasmallhammer,nottoolooseortootight,packedtheboltswiththecorrespondingsealscrewholeshouldbemarked.6.4.5.4.2couplingreamedandpairingsisclosetothediameterofboltbearinggoodhingeholes,dressedwithagoodtwocouplingboltsbeforeyoucanmovetherotor,boring-reamingholeinturn.Couplingboltsmustbetightcouplingissymmetricaldiameter,inboring,reaming,twoboltsout.Wellboring,hingeboltholeflangewithcouplingofvertical,notoblique.Duetothecouplingboltsinaccordancewithhingeholescorrespondingtothediameterofthescrewholesonebyoneafterprocessing,processingbackboltinstallationlocationcannotbechanged,soaccordingtoboltaftertheactualweightdifferenceofnutandlockwashertomatch.Generalrequirementsforcouplingtwosymmetricaldiameterbolt,nutandlockwasher'stotalweightdifferenceshouldnotbegreaterthan10gandknocksstampedmark.(SeeFigure18)Thecouplingboltsapplylubricant,andthengentlywithcopperhome,nottoolooseortootight.BoltAssemblyisfinished,symmetricaltighteningallboltsto30%,50%,70%,100%force,andcheckthecouplingflutterandbeforeconnectingthecirclegraduallychangesitsvalueshouldbelessthan0.02mm.Tighteningtorqueofthecouplingboltsshallcomplywiththetechnicalrequirementsmanufacturersdrawings,withadynamometricwrenchorlogtensiontools.Threewheelrotorswingtestcouplingconnectionsshouldbechecked:takingleave,6、封样计划:施工单位及分包单位应制定详细的封样计划。序号材料设备名称技术要求品牌要求拟封样时间备注7、封样的使用:应确保厂家后续到货与相应所封样品一致。①确认程序:材料到货后,施工单位应立即通知监理单位,由施工单位、监理共同确定该批材料的抽样比例,按照该比例随机抽取样品后,当场将抽取样品与封样样品对比,如双方共同认定两者一致,则双方方共同在材料进场报验单上签字认可,该批材料准予进场,必要时通知建设单位和管理公司;否则,不予接收。②确认流程:施工材料、流程图地形平坦开阔,地层由第四系全新冲积层,第四系上更新统冲层组成,局部表覆第四系全新统人工堆积层。第四系全新统冲积层厚度约25~50m,岩性主要为黏土、粉质黏土、粉土、粉砂、细砂;第四系上更新统冲积层厚度大于50m,岩性主要为黏性土、粉土、粉细砂等。管桩深度范围内地层主要为:粉土、黏土、粉质黏土,局部表层为杂填土。couplingCentreshallbechecked,thesecondpouredconcretestrengthofmorethan70%.Intheprocessofreamingorboring,apartfromthespecialprovisionsinfactory,doesnotallowanyworkthatmayaffectthecouplingCentre,suchasirrigation,tocylinderconnectionstofloodthecondenserpipesandsoon.Wellboring,hingeboltholeflangewithcouplingofvertical,notoblique.Mountingboltsshouldbeaddedlubricants,typinggentlywithasmallhammer,nottoolooseortootight,packedtheboltswiththecorrespondingsealscrewholeshouldbemarked.6.4.5.4.2couplingreamedandpairingsisclosetothediameterofboltbearinggoodhingeholes,dressedwithagoodtwocouplingboltsbeforeyoucanmovetherotor,boring-reamingholeinturn.Couplingboltsmustbetightcouplingissymmetricaldiameter,inboring,reaming,twoboltsout.Wellboring,hingeboltholeflangewithcouplingofvertical,notoblique.Duetothecouplingboltsinaccordancewithhingeholescorrespondingtothediameterofthescrewholesonebyoneafterprocessing,processingbackboltinstallationlocationcannotbechanged,soaccordingtoboltaftertheactualweightdifferenceofnutandlockwashertomatch.Generalrequirementsforcouplingtwosymmetricaldiameterbolt,nutandlockwasher'stotalweightdifferenceshouldnotbegreaterthan10gandknocksstampedmark.(SeeFigure18)Thecouplingboltsapplylubricant,andthengentlywithcopperhome,nottoolooseortootight.BoltAssemblyisfinished,symmetricaltighteningallboltsto30%,50%,70%,100%force,andcheckthecouplingflutterandbeforeconnectingthecirclegraduallychangesitsvalueshouldbelessthan0.02mm.Tighteningtorqueofthecouplingboltsshallcomplywiththetechnicalrequirementsmanufacturersdrawings,withadynamometricwrenchorlogtensiontools.Threewheelrotorswingtestcouplingconnectionsshouldbechecked:takingleave,8、对材料、设备的要求①、针对甲控材料:a、必须按照招标文件要求提取样品,按照封样制度进行报审,并通过监理和甲方确认封存。b、批量进场后监理单位派专人,对每一部位使用情况检查,对照封件落实。c、需进行二次复试的材料,经复试合格,方可投入工程使用。②、针对施工主要材料:a、经监理对照技术参数要求做封存。b、批量进场后,经专业监理工程师对每一部位使用情况检查,对照封存样品落实。c、需进行二次复试的材料,经复试合格,方可投入工程使用。甲控材料样品确认单责任部门:编号:工程名称地形平坦开阔,地层由第四系全新冲积层,第四系上更新统冲层组成,局部表覆第四系全新统人工堆积层。第四系全新统冲积层厚度约25~50m,岩性主要为黏土、粉质黏土、粉土、粉砂、细砂;第四系上更新统冲积层厚度大于50m,岩性主要为黏性土、粉土、粉细砂等。管桩深度范围内地层主要为:粉土、黏土、粉质黏土,局部表层为杂填土。couplingCentreshallbechecked,thesecondpouredconcretestrengthofmorethan70%.Intheprocessofreamingorboring,apartfromthespecialprovisionsinfactory,doesnotallowanyworkthatmayaffectthecouplingCentre,suchasirrigation,tocylinderconnectionstofloodthecondenserpipesandsoon.Wellboring,hingeboltholeflangewithcouplingofvertical,notoblique.Mountingboltsshouldbeaddedlubricants,typinggentlywithasmallhammer,nottoolooseortootight,packedtheboltswiththecorrespondingsealscrewholeshouldbemarked.6.4.5.4.2couplingreamedandpairingsisclosetothediameterofboltbearinggoodhingeholes,dressedwithagoodtwocouplingboltsbeforeyoucanmovetherotor,boring-reamingholeinturn.Couplingboltsmustbetightcouplingissymmetricaldiameter,inboring,reaming,twoboltsout.Wellboring,hingeboltholeflangewithcouplingofvertical,notoblique.Duetothecouplingboltsinaccordancewithhingeholescorrespondingtothediameterofthescrewholesonebyoneafterprocessing,processingbackboltinstallationlocationcannotbechanged,soaccordingtoboltaftertheactualweightdifferenceofnutandlockwashertomatch.Generalrequirementsforcouplingtwosymmetricaldiameterbolt,nutandlockwasher'stotalweightdifferenceshouldnotbegreaterthan10gandknocksstampedmark.(SeeFigure18)Thecouplingboltsapplylubricant,andthengentlywithcopperhome,nottoolooseortootight.BoltAssemblyisfinished,symmetricaltighteningallboltsto30%,50%,70%,100%force,andcheckthecouplingflutterandbeforeconnectingthecirclegraduallychangesitsvalueshouldbelessthan0.02mm.Tighteningtorqueofthecouplingboltsshallcomplywiththetechnicalrequirementsmanufacturersdrawings,withadynamometricwrenchorlogtensiontools.Threewheelrotorswingtestcouplingconnectionsshouldbechecked:takingleave,承包单位填写《工程物资进场报验表》材料退场监理工程师审核方法:审核证明资料进场材料检验进行验证承包单位使用承包单位填写《甲控材料/设备计划申请表》建设(管理公司)/监理单位审核提出审核意见并监督跟踪材料封样(相关方一起封样确认)承包单位签订订货合同组织材料进场提交材料进场计划不合格报送单位样品名称使用部位样品规格样品配置样品厂家封样形式□实物□照片□其他承包单位意见项目经理签字:年月日监理单位意见总监签字:年月日设计单位(方案、施工图及专业技术咨询单位)意见签字:年月日建设单位意见项目经理签字:年月日业主意见签字:年月日注:1、甲控材料指招标文件中业主重点控制的材料。2、业主仅对甲控材料的颜色、样式等确认签字。3、本表一式三份,承包单位、监理单位和建设单位各留存一份。地形平坦开阔,地层由第四系全新冲积层,第四系上更新统冲层组成,局部表覆第四系全新统人工堆积层。第四系全新统冲积层厚度约25~50m,岩性主要为黏土、粉质黏土、粉土、粉砂、细砂;第四系上更新统冲积层厚度大于50m,岩性主要为黏性土、粉土、粉细砂等。管桩深度范围内地层主要为:粉土、黏土、粉质黏土,局部表层为杂填土。couplingCentreshallbechecked,thesecondpouredconcretestrengthofmorethan70%.Intheprocessofreamingorboring,apartfromthespecialprovisionsinfactory,doesnotallowanyworkthatmayaffectthecouplingCentre,suchasirrigation,tocylinderconnectionstofloodthecondenserpipesandsoon.Wellboring,hingeboltholeflangewithcouplingofvertical,notoblique.Mountingboltsshouldbeaddedlubricants,typinggentlywithasmallhammer,nottoolooseortootight,packedtheboltswiththecorrespondingsealscrewholeshouldbemarked.6.4.5.4.2couplingreamedandpairingsisclosetothediameterofboltbearinggoodhingeholes,dressedwithagoodtwocouplingboltsbeforeyoucanmovetherotor,boring-reamingholeinturn.Couplingboltsmustbetightcouplingissymmetricaldiameter,inboring,reaming,twoboltsout.Wellboring,hingeboltholeflangewithcouplingofvertical,notoblique.Duetothecouplingboltsinaccordancewithhingeholescorrespondingtothediameterofthescrewholesonebyoneafterprocessing,processingbackboltinstallationlocationcannotbechanged,soaccordingtoboltaftertheactualweightdifferenceofnutandlockwashertomatch.Generalrequirementsforcouplingtwosymmetricaldiameterbolt,nutandlockwasher'stotalweightdifferenceshouldnotbegreaterthan10gandknocksstampedmark.(SeeFigure18)Thecouplingboltsapplylubricant,andthengentlywithcopperhome,nottoolooseortootight.BoltAssemblyisfinished,symmetricaltighteningallboltsto30%,50%,70%,100%force,andcheckthecouplingflutterandbeforeconnectingthecirclegraduallychangesitsvalueshouldbelessthan0.02mm.Tighteningtorqueofthecouplingboltsshallcomplywiththetechnicalrequirementsmanufacturersdrawings,withadynamometricwrenchorlogtensiontools.Threewheelrotorswingtestcouplingconnectionsshouldbechecked:takingleave,",)

提供项目部封样间管理制度,项目部管理制度大全会员下载,编号:1700845518,格式为 docx,文件大小为4页,请使用软件:wps,office word 进行编辑,PPT模板中文字,图片,动画效果均可修改,PPT模板下载后图片无水印,更多精品PPT素材下载尽在某某PPT网。所有作品均是用户自行上传分享并拥有版权或使用权,仅供网友学习交流,未经上传用户书面授权,请勿作他用。若您的权利被侵害,请联系963098962@qq.com进行删除处理。

下载

下载 下载

下载 下载

下载 下载

下载 下载

下载 下载

下载 下载

下载 下载

下载 下载

下载 下载

下载 下载

下载 下载

下载