耐热钢德国DIN标准,德国标准DIN

本作品内容为耐热钢德国DIN标准,格式为 doc ,大小 169512 KB ,页数为 6页

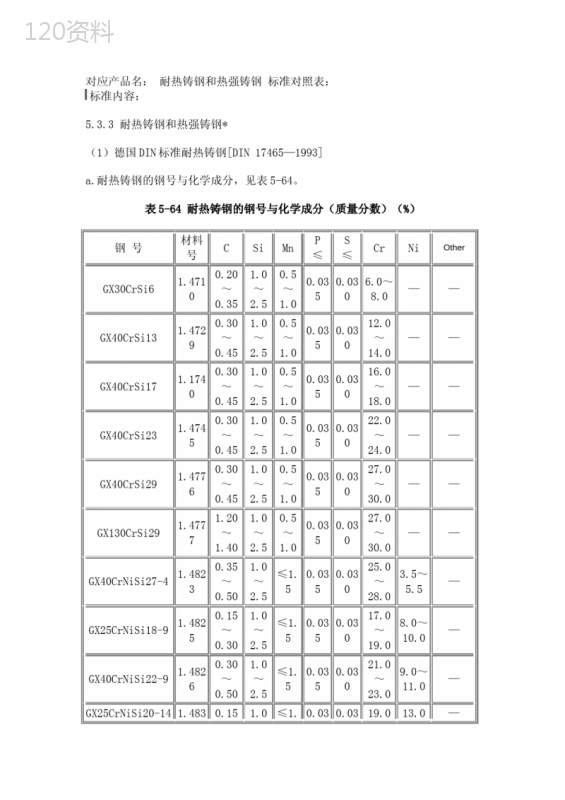

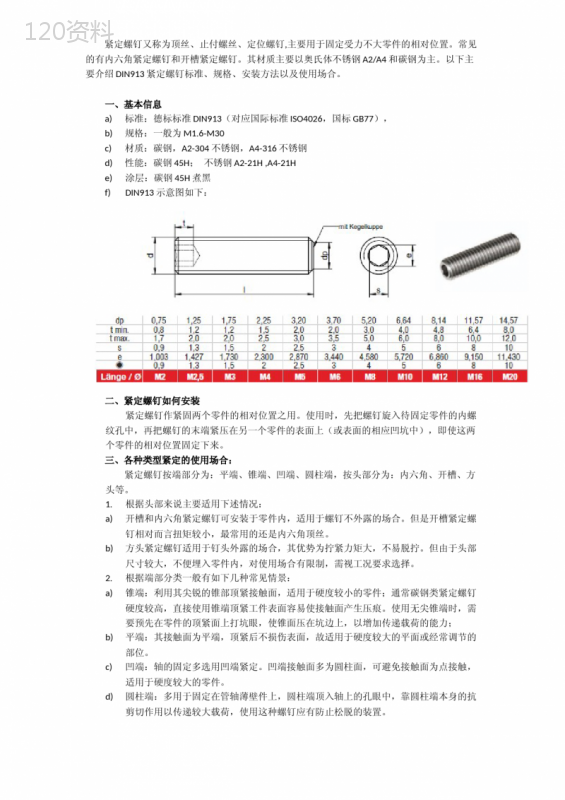

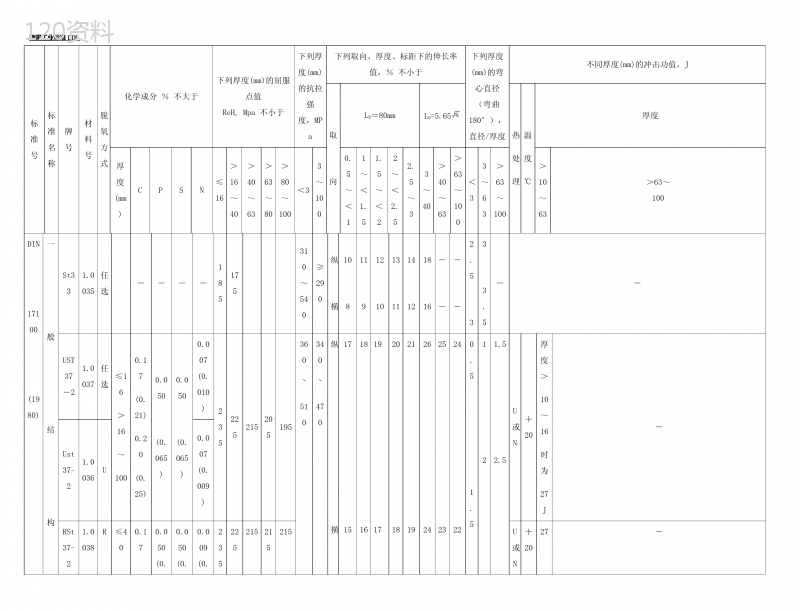

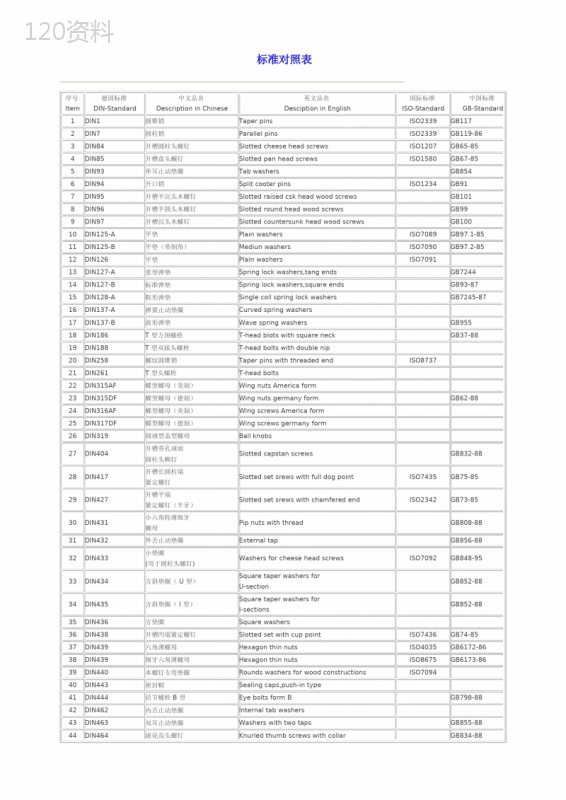

('对应产品名:耐热铸钢和热强铸钢标准对照表:标准内容:5.3.3耐热铸钢和热强铸钢(1)德国DIN标准耐热铸钢[DIN17465—1993]a.耐热铸钢的钢号与化学成分,见表5-64。表5-64耐热铸钢的钢号与化学成分(质量分数)(%)钢号材料号CSiMnP≤S≤CrNiOtherGX30CrSi61.47100.20~0.351.0~2.50.5~1.00.0350.0306.0~8.0——GX40CrSi131.47290.30~0.451.0~2.50.5~1.00.0350.03012.0~14.0——GX40CrSi171.17400.30~0.451.0~2.50.5~1.00.0350.03016.0~18.0——GX40CrSi231.47450.30~0.451.0~2.50.5~1.00.0350.03022.0~24.0——GX40CrSi291.47760.30~0.451.0~2.50.5~1.00.0350.03027.0~30.0——GX130CrSi291.47771.20~1.401.0~2.50.5~1.00.0350.03027.0~30.0——GX40CrNiSi27-41.48230.35~0.501.0~2.5≤1.50.0350.03025.0~28.03.5~5.5—GX25CrNiSi18-91.48250.15~0.301.0~2.5≤1.50.0350.03017.0~19.08.0~10.0—GX40CrNiSi22-91.48260.30~0.501.0~2.5≤1.50.0350.03021.0~23.09.0~11.0—GX25CrNiSi20-141.4830.151.0≤1.0.030.0319.013.0—2~0.30~2.5550~21.0~15.0GX40CrNiSi25-121.48370.30~0.501.0~2.5≤1.50.0350.03024.0~26.011.0~14.0—GX40CrNiSi25-201.48480.30~0.501.0~2.5≤1.50.0350.03024.0~26.019.0~21.0—GX40CrNiSi38-181.48650.30~0.501.0~2.5≤1.50.0350.03017.0~19.036.0~39.0—GX40CrNiSi35-251.48570.30~0.501.0~2.5≤1.50.0350.03024.0~26.034.0~36.0—GX30CrNiSiNb24-241.48550.25~0.400.5~2.0≤1.50.0350.03023.0~25.023.0~25.0Nb1.2~1.8GX40CrNiSiNb38-181.48490.30~0.501.0~2.5≤1.50.0350.03017.0~19.036.0~39.0Nb1.2~1.8GX40CrNiSiNb35-251.48520.35~0.451.0~2.5≤1.50.0350.03024.0~26.033.0~35.0Nb0.8~1.8G-CoCr282.47780.10~0.200.5~1.5≤1.50.0350.03027.0~30.0—Co18.0~52.0G-NiCr28W2.48790.35~0.500.5~2.0≤1.50.0350.03027.0~30.047.0~50.0W4.0~5.5b.耐热铸钢的室温力学性能,见表5-56。表5-56耐热铸钢的室温力学性能钢号材料号铸钢件状态力学性能(不小于)硬度≤HBS30σ0.2/MPaσb/MPaδ5(%)铁素体形GX30CrSi61.4710800~850oC退———300火GX40CrSi131.4729300GX40CrSi171.1740300GX40CrSi23GX40CrSi29GX130CrSi291.47451.47761.4777铸态————铁素体-奥氏体型GX40CrNiSi27-41.4823铸态————奥氏体型GX25CrNiSi18-91.4825铸态23044015—GX40CrNiSi22-91.48262304408GX25CrNiSi20-141.483223044010GX40CrNiSi25-121.48372304407GX40CrNiSi25-201.48482304406GX40CrNiSi38-181.48652304005GX40CrNiSi35-251.48572304405GX30CrNiSiNb24-241.48552304405GX40CrNiSiNb38-181.48492204005GX40CrNiSiNb35-251.48522204005GCoCr282.4778———GNiCr28W2.4879———c.耐热铸钢的高温力学性能,见表5-66。表5-66耐热铸钢的高温力学性能钢号材料号下列温度时1%-10000h的蠕变强度/MPa最高工作温度/oC600oC700oC800oC900oC1000oC1100oCGX30CrSi6GX40CrSi13GX40CrSi17GX40CrSi231.47101.47291.17401.474519.5222226899112.52.53.55—111.5————————7508509001050GX40CrSi29GX130CrSi291.47761.477726—11—5—1.5—————11501100GX40CrNiSi27-41.4823—21941.5—1100GX25CrNiSi18-9GX40CrNiSi22-9GX25CrNiSi20-14GX40CrNiSi25-12GX40CrNiSi25-201.48251.48261.48321.48371.4848788282——444646506622232326369.5101012.517———5.57—————90095095010501100GX40CrNiSi38-18GX40CrNiSi35-251.48651.4857——5570324016206.58—210501100GX30CrNiSiNb24-24GX40CrNiSiNb38-18GX40CrNiSiNb35-251.48551.48491.4852———8060724638412220227.589——2105010001100GCoCr28GNiCr28W2.47782.4879——707034411622610—411001150(2)德国DIN标准铁素体热强铸钢[DIN17245—1987]a.铁素体热强铸钢的钢号与化学成分,见表5-67。表5-67铁素体热强铸钢的钢号与化学成分(质量分数)(%)钢号材料号CSiMnP≤S≤CrNi其他GS-C251.061901.8~0.230.30~0.600.50~0.800.0200.015≤0.30——GS-22Mo41.54190.18~0.230.30~0.600.50~0.800.0200.015≤0.30—Mo0.35~0.45GS-17CrMo551.73570.15~0.200.30~0.600.50~0.800.0200.0151.00~1.50—Mo0.45~0.55GS-18CrMo9101.73790.15~0.200.30~0.600.50~0.800.0200.0152.00~2.50—Mo0.90~1.10GS-17CrMoV5111.77090.15~0.200.30~0.600.50~0.800.0200.0151.20~1.50—Mo0.90~1.10V0.20~0.30G-XCrNi121.41070.06~0.100.10~0.400.50~0.800.0300.02011.5~12.50.80~1.50Mo≤0.50N≤0.05G-XCrMoV1211.49310.20~0.260.10~0.400.50~0.800.0300.02011.3~12.20.70~1.00Mo1.00~1.20V0.25~0.35(W≤0.50)b.铁素体热强铸钢的力学性能,见表5-68。表5-68铁素体热强铸钢的力学性能钢号材料号σb/MPa下列温度时的σ0.2/MPaδ5>=(%)AKV/>J20oC200oC300oC350oC400oC450oC500oC550oCGS-C251.0619440~5902451751451351301252227GS-22Mo41.5419440~5902451901651551501451352227GS-17CrMo551.7357490~6403152552302152051901801602027GS-18CrMo9101.7379590~7404003553453303153052802401840GS-17CrMoV5111.7709590~7804403853653503353203002601527G-XCrNi121.4107540~6903552752652602551835G-XCrMoV1211.4931740~8803854504304103903703402901521',)

提供耐热钢德国DIN标准,德国标准DIN会员下载,编号:1700818354,格式为 docx,文件大小为6页,请使用软件:wps,office word 进行编辑,PPT模板中文字,图片,动画效果均可修改,PPT模板下载后图片无水印,更多精品PPT素材下载尽在某某PPT网。所有作品均是用户自行上传分享并拥有版权或使用权,仅供网友学习交流,未经上传用户书面授权,请勿作他用。若您的权利被侵害,请联系963098962@qq.com进行删除处理。

下载

下载 下载

下载 下载

下载 下载

下载 下载

下载 下载

下载 下载

下载 下载

下载 下载

下载 下载

下载 下载

下载 下载

下载