各类阀门型号大全,各类阀门型号大全文库

本作品内容为各类阀门型号大全,格式为 doc ,大小 479272 KB ,页数为 16页

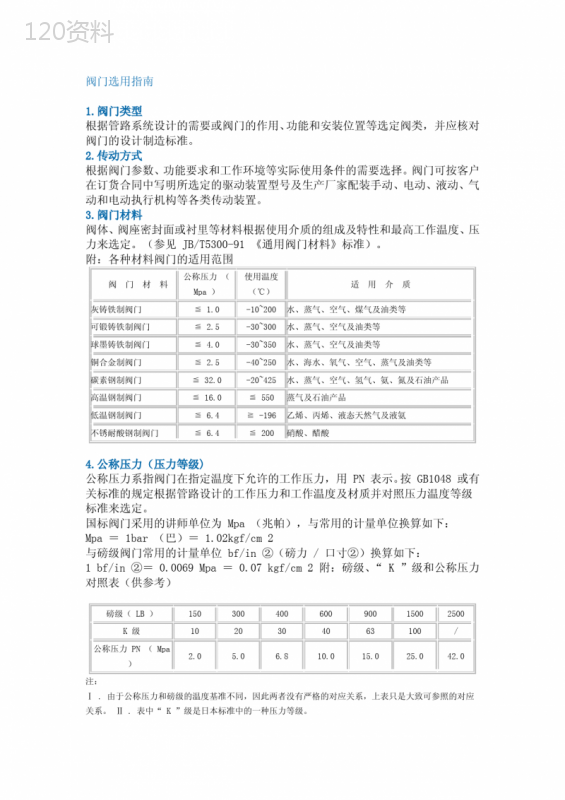

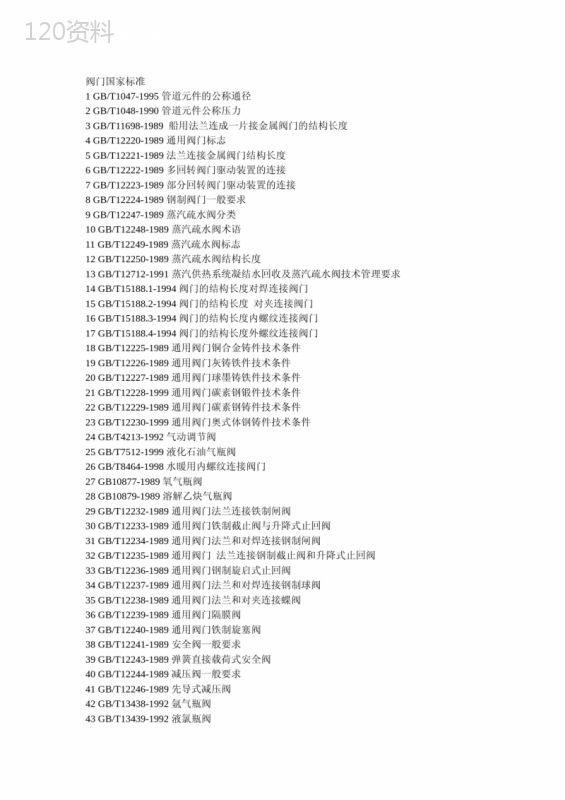

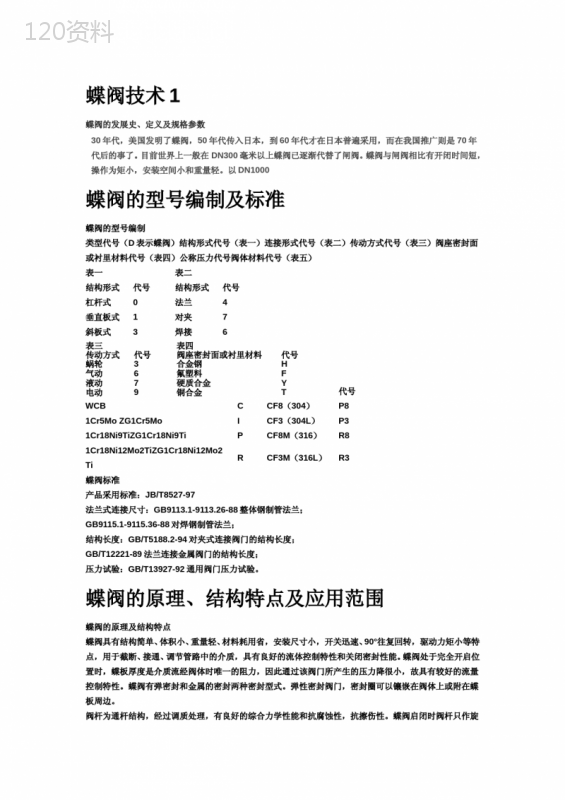

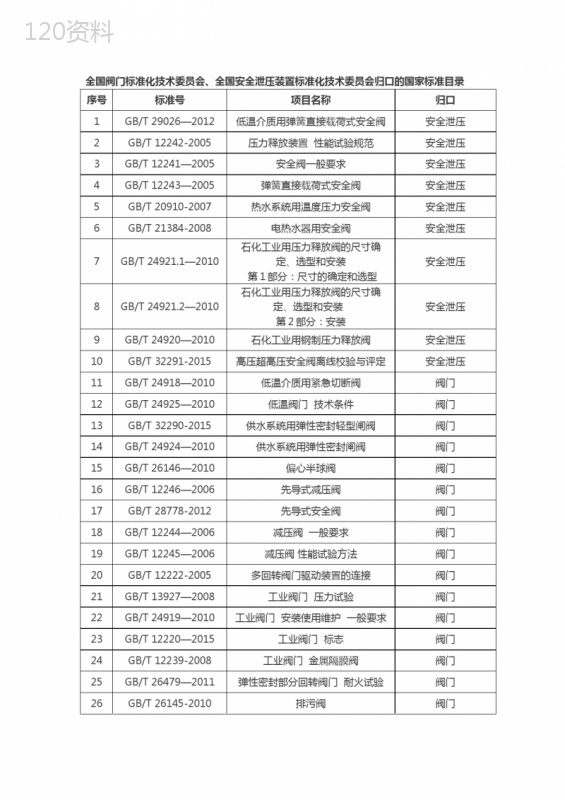

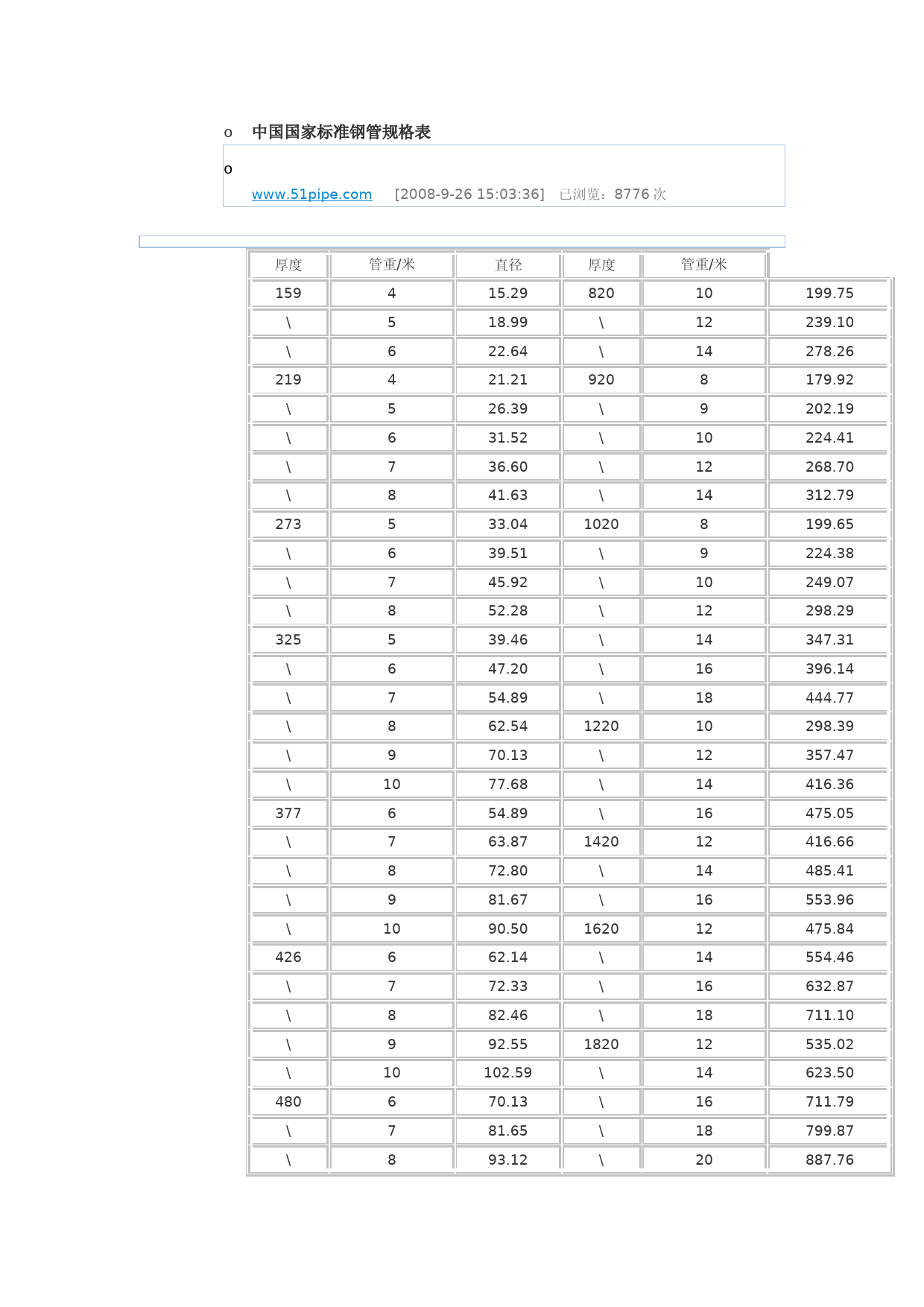

('阀门选用指南1.阀门类型根据管路系统设计的需要或阀门的作用、功能和安装位置等选定阀类,并应核对阀门的设计制造标准。2.传动方式根据阀门参数、功能要求和工作环境等实际使用条件的需要选择。阀门可按客户在订货合同中写明所选定的驱动装置型号及生产厂家配装手动、电动、液动、气动和电动执行机构等各类传动装置。3.阀门材料阀体、阀座密封面或衬里等材料根据使用介质的组成及特性和最高工作温度、压力来选定。(参见JB/T5300-91《通用阀门材料》标准)。附:各种材料阀门的适用范围阀门材料公称压力(Mpa)使用温度(℃)适用介质灰铸铁制阀门≦1.0-10~200水、蒸气、空气、煤气及油类等可锻铸铁制阀门≦2.5-30~300水、蒸气、空气及油类等球墨铸铁制阀门≦4.0-30~350水、蒸气、空气及油类等铜合金制阀门≦2.5-40~250水、海水、氧气、空气、蒸气及油类等碳素钢制阀门≦32.0-20~425水、蒸气、空气、氢气、氨、氮及石油产品高温钢制阀门≦16.0≦550蒸气及石油产品低温钢制阀门≦6.4≧-196乙烯、丙烯、液态天然气及液氨不锈耐酸钢制阀门≦6.4≦200硝酸、醋酸4.公称压力(压力等级)公称压力系指阀门在指定温度下允许的工作压力,用PN表示。按GB1048或有关标准的规定根据管路设计的工作压力和工作温度及材质并对照压力温度等级标准来选定。国标阀门采用的讲师单位为Mpa(兆帕),与常用的计量单位换算如下:Mpa=1bar(巴)=1.02kgf/cm2与磅级阀门常用的计量单位bf/in②(磅力/口寸②)换算如下:1bf/in②=0.0069Mpa=0.07kgf/cm2附:磅级、“K”级和公称压力对照表(供参考)磅级(LB)15030040060090015002500K级1020304063100/公称压力PN(Mpa)2.05.06.810.015.025.042.0注:Ⅰ.由于公称压力和磅级的温度基准不同,因此两者没有严格的对应关系,上表只是大致可参照的对应关系。Ⅱ.表中“K”级是日本标准中的一种压力等级。5.连接形式一般采用法兰、焊接(对焊、承、承插焊)和螺纹连接等方式。连接端的尺寸和形式一般根据公称压力、通径和材质等要求按有关标准选定。对国标阀门说明如下:1.法兰连接尺寸和密封面型式可按GB9113、GB9115、GB4261和原机标JB79、JB78等有关标准选定。如与本样本所选标准或尺寸一符时,则须在订货合同中注明。2.对焊端连接按GB12224的规定。3.承插焊端连接按JB/T1751的规定。4.内螺纹连接按GB7306圆锥管螺纹的规定。5.外螺纹连接按FB7307管螺纹或GB196、GB197普通螺纹的规定。对通径DN大于50mm对焊端电站阀门,应根据接管尺寸(外径X壁厚)确定孔径及坡口形式、尺寸6.结构长度:可按有关标准选定或按客房的要求确定。7.结构形式:可根据密封元件和流道的形式选择。8.公称通径(规格)可按GB1047或有关标准的规定来选定。国标阀门以DN表示,单位为毫米(mm),磅级阀门以NPS表示,单位为口寸(in)。9.阀门型号:国标阀门按JB308-75《阀门型号编制办法》的规定。对特殊、非标及磅级阀门的型号,可参考JB308-75由企业自编。10.客户应根据本样本所列的阀门型号规格选用。另有特殊要求时,应详细加以说明。11.样本中的产品重量为近似值,以代参改。12.电动阀门中的民装附件电控箱和自动调节阀的伺服放大器、操作箱均由客户自配,或由公司配套提供但价格另计。阀门型号编制办法(JB308-75)1.阀门产品型号由七个单元组成按下列顺序编制。类型代号传动方式连接形式代号结构形代号阀座密封面或实衬里材料代号公称压力数值阀体材料代号2.类型代号用汉语拼音字母表示,按表1的规定。表1类型代号类型代号类型代号闸阀Z蝶阀D安全阀A截止阀J隔膜阀G减压阀Y节流阀L旋塞阀X疏水阀S球阀Q止回阀H3.传动方式代号用阿拉伯数字表示,按表2的规定。表2传动方式代号传动方式代号电磁动0伞齿动5电磁液动1气动6电液动2液动7蜗轮3气液动8正齿轮4电动9注:(1)手轮、手柄和板手传动以及安全阀、减压阀、疏水阀省略本代号。(2)对于气动或液动:常开式用6K、7K表示:常闭式用6B、7B表示:气动带手动6S表示。防爆电动用“9B”表示。(3)连接形式代号用阿拉伯数字表示,按表3的规定。表3连接形式内螺纹外螺纹法兰焊接对夹卡箍卡套代号12467894.结构形式代号用阿拉伯数字表示,按表4-13的规定表4闸阀结构形式代号明杆楔式弹性闸板0刚性单闸板1双闸板2平行式单闸板3双闸板4暗杆楔式单闸板5双闸板6表5截止阀结构形式节流阀直通式角式直流式平衡直通式角式代号14567表6上回阀结构形式直通升降式升降立式单瓣旋启式多瓣旋启式双瓣旋启式代号12456表7隔膜阀结构形式屋脊式截止式直流板式闸板式代号1357表8球阀结构形式浮动球阀直通式浮动球三通式固定球直通式固定球三通式代号1L形T形7845表9蝶阀结构形式垂直板式斜板式杠杆式代号130表10>减压阀结构形式薄膜式弹簧薄膜式活塞式波纹管式杠杆式代号12345表11硫水阀结构形式浮球式钟形浮子式脉冲式热动力式代号1599表12安全阀结构形式代号弹簧封闭带散热片全启式0微启式1全启式2不封闭带扳手全启式3双弹簧微启式4微启式5全启式6微启式7带控制机构全启式8脉冲式9注:杠杆式安全阀在类型代号前加“G”汉语拼音字母表13旋塞阀结构形式直通填料式三通填料式直通油封式三通油封式代号34786.座密封面或衬里材料代号用汉语拼音字母表示,按表14规定表14阀座密封面或衬里材料代号阀座密封面或衬里材料代号阀座密封面或衬里材料代号铜合金T巴氏合金B衬胶J橡胶X合金钢H搪瓷C尼龙塑料N渗氮钢D衬铅Q氟塑料F硬质合金Y渗硼钢P注:由阀体直接加工的阀座密封面材料代号“W”表示:当阀座和阀瓣(闸板)密封面材料不同时,用低硬度材料代号表示(隔膜阀除外)7.公称压力,按JB74-59“管路附件公称压力,试验压力和工作压力”的规定。用于电站工业的阀门,当介质最高温度超过530℃时,按JB74-59第5条规定,标注工作压力8.阀体材料代号用汉语拼音表示,按表15规定.表15阀体材料代号阀体材料代号阀体材料代号灰铸铁Z铜合金T1Cr18Ni9TiP可锻铸铁K碳钢C1Cr18Ni12Mo2TIR球墨铸铁QCr5MoI12Cr1MoVV注:PN≦16kgf/cm2的灰铸铁阀体和PN≧25kgf/cm2的碳素钢阀体,省略本单元。6.座密封面或衬里材料代号用汉语拼音字母表示,按表14规定表14阀座密封面或衬里材料代号阀座密封面或衬里材料代号阀座密封面或衬里材料代号铜合金T巴氏合金B衬胶J橡胶X合金钢H搪瓷C尼龙塑料N渗氮钢D衬铅Q氟塑料F硬质合金Y渗硼钢P注:由阀体直接加工的阀座密封面材料代号“W”表示:当阀座和阀瓣(闸板)密封面材料不同时,用低硬度材料代号表示(隔膜阀除外)7.公称压力,按JB74-59“管路附件公称压力,试验压力和工作压力”的规定。用于电站工业的阀门,当介质最高温度超过530℃时,按JB74-59第5条规定,标注工作压力8.阀体材料代号用汉语拼音表示,按表15规定.表15阀体材料代号阀体材料代号阀体材料代号灰铸铁Z铜合金T1Cr18Ni9TiP可锻铸铁K碳钢C1Cr18Ni12Mo2TIR球墨铸铁QCr5MoI12Cr1MoVV注:PN≦16kgf/cm2的灰铸铁阀体和PN≧25kgf/cm2的碳素钢阀体,省略本单元国标阀门采用主要标准汇总类别设计制造压力温度等级结构长度①连接端尺寸检验与试验法兰端对焊端闸阀钢制、楔制GB12234GB9131GB12221GB9112GB9113GB12224JB/T9092(代替ZBJ16006)铁制、楔制GB12232GB4216.1GB12232GB12221GB4216GB9113/GB/T13927(代替GB4981)管线钢制、平板JB/T5298GB9131JB/T5298GB9113GB9115GB12224GB/T13927铁制对夹、平板JB/TQ648GB4216.1GB12232JB/T5298GB4216.2-5/JB/9092截止阀钢制GB12235GB9131GB12221GB9112GB9113GB12224JB/9092铁制GB12233GB4216.1GB12232GB12221GB12233GB4216GB9113/GB/T13927针形JB/T7747GB9131GB/T15188//JB/T9092球阀钢制GB12237GB9131GB12221GB12237GB9113GB12224JB/T9092铁制、GB/T15185GB4216.1GB12386GB/T15185GB12221B/T15188.3GB9113GB4216GB12380/GB/T13927管线钢制JB/T7745GB9131GB12221JB/T7745GB9113GB/T13402GB12224JB/T9092止回阀钢制、旋启式GB12236GB9131GB12221GB9112GB9113GB1224JB/T9092铁制、旋启式GB/T13932GB4216.1GB12232GB12221GB/T13932GB4216GB9113/B/T13927钢制、升降式GB12235GB9131GB12221GB9112GB9113GB12224JB/T9092铁制、升降式GB12233GB4216.1GB12232GB12221GB12233GB4216GB9113/GB/T13927蝶阀法兰、对夹GB12238GB9131GB4216.1GB12232GB12221GB4216.2-4GB9113GB12224GB/13927金属密封JB/T8527GB9131GB12386GB12221GB/T15188.2GB9113GB9115GB12380/GB/T13927烟道JB/T8692GB9131GB12221GB/T15188.2GB9115/JB/T9092隔膜阀GB12239选定GB12221GB12239GB4216GB9113/铁制旋塞阀GB12240GB4216.1GB12232GB12221GB12240GB4216/安全阀GB12241GB12243/GB2203GB9113JB/T2769GB12224GB12224减压阀GB12244GB12246/JB/T2205GB4216GB9113GB12224蒸气疏水阀JB/T9093(代替/JB/T12250GB4216GB9113GB12224ZBJ16007)缩径锻钢阀门JB/T7746(代替ZBJ16005)GB9131JB/T7746GB12221JB/T7746GB/T15188.1GB9113/低温阀门JB/T7749/GB12221②JB/T79GB12224电站阀门JB/T3595(E101)JB/T3595(E101)JB/T3595(E101)/GB12224(ASNIB16.25)JB/T3595(E101)注:①除法兰和对焊端外,承插焊连接尺寸采用JB/T1751,内、外螺纹连接的尺寸分别采用GB7306、GB7307。②JB/T79-94机械待业标准中,系列1法兰连接尺寸与国际GB9113-88互换,系列2尺寸与原机标JB79-59互换。美标及日标钢制阀门采用主要标准美标钢制阀门采用主要标准类别设计制造压力温度等级结构长度连接端尺寸检验与试验法兰端对焊端ANSI/API美标阀门铸钢楔式闸阀AP1600ANSIB16.34ANSIB16.34ANSIB16.10ANSIB16.5ANSIB16.25API598铸钢截止阀ANSIB16.34ANSIB16.34ANSIB16.10ANSIB16.5ANSIB16.25API598铸钢旋启式止回阀ANSIB16.34ANSIB16.34ANSIB16.10ANSIB16.5ANSIB16.25API598API6D升降式止回阀API602ANSIB16.34ANSIB16.34ANSIB16.10ANSIB16.5/API598对夹式蝶阀API609ANSIB16.34API609//API598管线、法兰球阀API6DANSIB16.34ANSIB16.10ANSIB16.5MSS-SP44API605B16.25ANSI31.4B31.5API598API6D锻钢阀门API602ANSIB16.34API602API602内螺纹ANSIB2.1承插焊ABSUB16.11API598日标钢制阀门采用主要标准类别设计制造压力温度结构长度法兰端尺寸检验与试验JIS(10K20K)日标阀门铸钢楔式闸阀B2073B2083B2073B2083B2002B2212B2214B2003铸钢截止阀B2071B2081B2071B2081B2002B2212B2214B2003铸钢旋启式止回阀B2074B2084B2074B2084B2002B2212B2214B2003二体式法兰球阀API6DB2201(ANIB16.34)B2002(ANSIB16.10)B2212B2214B2003(API598)钢制阀门主要零件材料表(一)零件名称材料名称牌号标准号阀体阀盖支架启闭件碳素铸钢件WCA、WCB、WCCGB12229优质碳素钢20、25、30GB699高温钢ZG1Cr5Mo、ZG20CrMoV、ZG15Cr1Mo1VZBJC8015WC1、WC5、WC6、WC9GB/T52631Cr5MoGB122112CrMoV、12CrMoVAGB3077低温钢ZG0Cr18Ni9、ZG1Cr18Ni9、ZG0Cr18Ni9Ti、ZG1Cr18Ni9TiGB12230(GB2100)LCB、LC1、LC2、LC3JB/T72480Cr18Ni9、1Cr18Ni9、0Cr18Ni9Ti、1Cr18Ni9TiGB1220不锈耐酸钢ZG0Cr18Ni9、ZG0Cr18Ni9Ti、ZG00Cr18Ni10、ZG0Cr12MoTi、CF8、CF8M、CF3、CF3M、CF8CGB122301Cr18Ni9(302)、0Cr18Ni9(304)、1Cr17Ni2(431)、00Cr19Ni11(304L)、0Cr17Ni12Mo2(316)、ooCr17Ni14Mo2(316L)GB1220阀杆不锈铬钢1Cr13、2Cr13、3Cr13GB1220铬镍钢1Cr17Ni2、1Cr18Ni9铬镍钛钢1Cr18Ni9Ti铬镍钼钛钢1Cr18Ni12Mo2Ti、1Cr18Ni12Mo3Ti铬锰钼氮钢0Cr17Mn13Mo2V沉淀硬化型0Cr17Ni4Cu4Mo(17-4PH)铬硅钼钢4Cr9Si2、4Cr10Si2MoGB1221铬钼钒钢25Cr2MoV、25Cr2Mo1VGB3077渗氮钢38CrMoAL(318钢)阀杆螺母铸造铝青铜ZCuA19Mn2、ZCuA19Fe4ni4Mn2GB12225(GB1176)铸造铝黄铜ZcuZn25A16Fe3Mn3奥氏体高镍球铁D-2ASTM-A439阀体或阀座、启闭件的密封面铬不锈钢1Cr13、2Cr13、3Cr13GB1220不锈耐酸钢木体材料GB12230(GB2100)、GB1220钴铬钨合金D802(S111)、D812(S111)GB984喷焊合金粉末F101、F211、F311、F312,F322JB3168聚四氟乙烯SFB-1、SFB-2、SFB-3ZBG33002(HG2-534)ZBG33003(HG2-535)国标阀门试验压力值(MPa)试验项目磅级15030040060090015002500PsiMPaPsiMPaPsiMPaPsiMPaPsiMPaPsiMPaPsiMPa壳体试验4503.111257.8150010.3222515.3335023.1557538.4936764.4高压密封试验上密封试验3152.28155.611007.6163011.2244016.8408028.1687347.4低压密封试验60-100Psi/0.5-0.7MPa钢制阀门的压力-温度等级钢号基准温度(℃)工作温度(℃)10、20、25WCB2002503003504004254354454551.5CrMoZG20CrMo2003204504905005105155255355451.2CrlMov200320450510520530540550560570200325390430450470490500510520530540550200300400480520560590610630640660675690700PN(MPa)(MPa)最大工作压力ptmax(MPa)0.10.20.100.090.080.070.060.060.050.050.250.40.250.220.200.180.160.140.120.110.100.090.080.070.060.060.40.60.400.360.320.280.250.220.200.180.160.140.120.110.100.090.60.90.600.560.500.450.400.360.320.280.250.220.200.180.160.141.01.51.00.900.800.700.640.560.500.450.400.360.320.280.250.221.62.41.81.41.251.11.00.900.800.700.640.560.500.450.400.362.03.82.52.22.01.81.61.41.251.11.00.900.800.0700.640.564.06.04.03.63.22.82.52.22.01.81.61.41.251.11.00.906.49.66.45.65.04.54.03.63.22.82.52.22.01.81.61.410.015.010.09.08.07.06.45.65.04.54.03.63.22.82.52.216.024.016.014.012.511.210.09.08.07.16.45.65.04.54.03.620.030.020.018.016.014.012.511.210.09.08.07.16.45.65.04.525.038.025.022.520.018.016.014.012.511.210.09.08.07.16.45.632.048.032.028.025.022.520.018.016.014.012.511.210.09.08.07.140.056.040.036.032.028.025.022.520.018.016.014.012.511.210.09.050.070.050.045.040.036.032.028.025.022.520.018.016.014.012.511.264.090.064.056.050.045.040.036.032.028.025.022.520.018.016.014.080.0110.080.071.064.056.050.045.040.036.032.028.025.022.520.018.0100.0130.0100.090.080.071.064.056.050.045.040.036.032.028.025.022.0注:1最大工作压力指无冲击表压.2当工作温度为表中温度级之中间值时,可用内插法决定最大工作压力.磅级阀门试验压力值(Psi/MPa)试验项目磅级15030040060090015002500PsiMPaPsiMPaPsiMPaPsiMPaPsiMPaPsiMPaPsiMPa壳体试验4503.111257.8150010.3222515.3335023.1557538.4936764.4高压密封试验上密封试验3152.28155.611007.6163011.2244016.8408028.1687347.4低压密封试验60-100Psi/0.5-0.7MPa法兰和对焊连接标准级阀门的压力-温度等级最大允许非冲击压力值(MPa)介质温度Class150℃WCBWC6WC9C5LCCLCBCF8CF3CF8MCF3MMonel-29.38501001.961.921.772.0019.821.772.0019.821.772.0019.821.772.00①19.821.771.84②1.811.711.901.841.571.901.841.571.901.841.571.901.841.571.591.541.381502002501.581.401.211.581.401.211.581.401.211.581.401.211.581.401.211.581.401.211.391.261.171.391.261.171.391.261.171.391.261.171.391.261.173003503751.020.840.741.020.840.741.020.840.741.020.840.741.020.840.741.020.840.741.020.840.741.020.840.741.020.840.741.020.840.741.020.840.744004254500.650.360.47①0.650.360.470.650.360.470.650.360.470.650.360.470.650.360.470.650.360.470.650.360.470.650.360.470.650.360.470.650.364755005250.370.280.190.370.280.190.370.280.190.370.280.190.370.280.190.370.280.190.370.280.190.370.280.190.370.280.190.370.280.195405756250.13①0.130.13①0.130.13①0.130.130.130.130.130.130.130.130.130.130.130.130.13最大允许非冲击压力值(MPa)介质温度Class300℃WCBWC6WC9C5LCCLCBCF8CF8MCF3CF3MMonel-29.38501005.115.014.045.175.114.885.175.124.905.175.125.155.175.125.154.794.734.514.964.814.094.964.814.224.964.784.094.964.814.224.144.033.611502002504.524.384.074.644.554.454.664.484.425.024.484.635.024.484.634.404.274.063.633.283.053.853.773.343.633.283.053.853.773.343.363.303.283003503753.873.703.654.244.023.884.244.063.884.244.063.884.244.063.883.773.603.532.912.812.783.163.042.972.91]2.812.783.163.142.973.223.174004254503.452.882.003.663.513.383.663.513.383.063.453.093.452.882.003.242.731.982.752.722.692.912.872.812.752.722.692.912.872.814755005251.350.880.523.172.782.033.172.782.192.590.031.541.350.880.521.350.880.522.662.612.392.842.682.582.662.612.392.742.682.585405756251.280.851.641.171.170.882.182.012.502.412.182.011.312.502.410.340.660.451.311.831.83介质温度Class600℃WCBWC6WC9C5LCCLCBCF8CF3CF8MCF3MMonel-29.385010010.2110.029.281.3410.239.7510.3410.249.8110.3410.349.8110.34103410.319.579.469.029.929.578.189.929.578.189.939.638.449.939.638.448.288.067.211502002509.058.708.349.279.108.899.338.978.8410.049.769.2710.049.769.278.798.548.027.276.555.557.276.555.557.707.136.687.707.136.687.706.606.563003503757.757.397.298.498.057.768.498.057.768.498.057.768.498.057.767.547.197.065.815.615.555.815.615.556.336.085.946.336.085.946.556.556.550.66.905.754.017.327.026.767.327.026.767.326.906.186.905.754.016.485.463.965.495.435.375.495.435.375.825.735.625.825.735.626.456.334755005252.711.761.046.335.564.056.134.623.255.184.053.082.711.761.042.711.761.045.315.214.785.315.214.785.475.375.165.475.375.165405756252.551.760.682.602.361.742.341.760.904.364.012.624.364.012.624.994.823.654.994.823.65最大允许非冲击压力值(MPa)介质温度Class900℃WCBWC6WC9C5LCCLCBCF8CF8MCF3CF3MMonel-29.385010015.3215.0213.9115.5115.3414.6315.5215.5215.4615.5215.5215.4615.5215.5215.4614.3614.1913.3314.8914.3512.2614.8914.3512.2614.8914.3512.2614.8914.4412.6612.4112.0410.8215020025013.5713.1512.5213.9113.6213.3415.0614.6413.9015.0614.6413.9015.0614.6413.9013.1912.8012.1810.909.839.1610.909.839.1611.5510.7010.0211.5510.7010.0210.079.909.8430035037511.6211.0910.9412.7312.0711.6412.7312.0711.6412.7312.0711.06412.7312.0711.6411.3110.7910.598.728.428.338.728.428.339.499.138.919.499.138.919.839.839.8340042545010.358.636.0110.9810.5310.1410.9810.5310.1410.9810.359.2710.358.636.019.728.195.948.248.158.068.248.158.068.738.608.428.738.608.429.679.504755005254.062.641.559.508.348.089.196.924.887.776.084.634.062.641.554.062.641.557.977.827.167.977.827.168.218.057.748.218.057.745405756253.832.551.013.903.543.803.502.641.356.546.023.026.546.023.927.497.235.487.497.235.48介质温度Class1500℃WCBWC6WC9C5LCCLCBCF8CF8MCF3CF3MMonel-29.385010025.5325.0423.1925.8625.5724.3825.8625.8625.6725.8625.8625.6725.8625.8625.6723.9423.6522.5524.8123.9220.4124.8124.0621.1024.8124.0621.1024.8124.0621.1020.6920.1518.0415020025022.6121.9120.8623.1922.7422.2323.3222.4222.1125.1024.3923.1725.1024.3923.1721.9921.3420.2918.1716.3815.2718.1716.3815.2719.2717.8416.6919.2517.8416.6916.7816.4916.4030035037519.3718.4818.2321.2120.1219.4021.2120.1219.4021.2120.1219.4021.2120.1219.4018.8517.9817.6614.5314.0313.0814.5314.0313.8815.811502114.8515.8115.2114.8516.3816.3816.3840042545017.2514.3810.0218.2917.5516.9018.2917.5516.9018.2917.2515.4517.2514.3810.0216.2013.659.9013.7313.5813.4313.7313.5813.4314.5614.3314.0414.5614.3314.0416.7215.834755005256.774.442.5915.8313.9010.1315.8313.9010.9612.9510.137.706.674.402.596.774.402.5913.2813.0211.9413.2813.0211.9413.6813.4112.9013.6813.4112.905405756256.384.251.698.185.853.925.844.412.2510.9110.046.5410.9110.046.5412.4812.059.1312.4812.059.13注:①允许在450℃使用,但不推荐长时间使用温度超过425℃。②超过540℃只能使用对焊接连接,而不能采用法兰连接。③低温材料在低温材料状态下的工作压力不能超过常温时的额定压力值。在表列温度区间内的允许工作压力可采用质值法求得。工业用阀门压力试验标准执行标准GB/T13927-92《通用阀门压力试验》适用阀门闸阀、截止阀、蝶阀、止回阀、旋塞阀、隔膜阀试验要求:1、每台阀门出厂前,应在室温下整机进行压力试验。2、试验介质可选用水、煤油和粘度大于水的其它液体。3、试压时,应以正常方式关闭,应用驱动装置关闭阀门进行试压。试验内容及评及指标公称通径MM≤5060-200250-450≥500密封试验保压壳体试验1560180密封试验金属15303020非金属<15152060时间S1530试验压力液体20度下最大允许工作压力的1.1倍壳体20度下最大允许工作压力的1.5倍气体DN-DN2000.6MP8达到保压时间允许渗漏量试压持续时间内可见泄漏工业用阀门压力试验标准序号标准等级标准代号标准全称1国家标准GB12238-89通用阀门法兰和对夹连接蝶阀2国家标准GB13927-92工业阀门的压力试验3国家标准GB1074-70阀门公称通径标准4国家标准GB2555-2556-81一般用途法兰标准5国家标准GB9112-88对夹式蝶阀法兰连接标准6国家标准GB12221-89法兰连接金属阀门结构长度标准7行业、部标准JB308-75阀门型号编制方法8行业、部标准JB/T8527-97金属密封蝶阀制造与验收9国家标准GB12234-89法兰和对焊连接钢制闸阀10国家标准GB12232-89通用阀门、法兰连接铁制闸阀11国家标准GB/T15185-94铁制和铜制球阀12国家标准GB12237-89通用阀门、法兰和对焊连接钢制球阀13国家标准GB12240-89通用阀门、铁旋塞阀14国家标准GB12235-89法兰连接钢制截止阀和升降式上回阀15国家标准GB12239-89通用阀门隔膜阀16国家标准GB/T13932-92通用阀门铁制旋启式止回阀17国家标准GB1241-89安全阀18行业、部标准CJ/T3006-92铸铁镶铜升杆闸门1.阀门的分类按阀门的用途分截断用:截断管路中介质。如:闸阀、截止阀、球阀、旋塞阀、蝶阀等止回用:防止介质倒流。如:止回阀调节用:调节压力和流量。如:调节阀、减压阀、节流阀、蝶阀、V形开口球阀、平衡阀等分配用:改变管路中介质流向,分配介质。如:分配阀、三通或四通球阀、旋塞阀等安全用:用于超压安全保护。如:安全阀、溢流阀。其它特殊用途:如蒸汽疏水阀、空气疏水阀、排污阀、放空阀、呼吸阀、排渣阀、温度调节阀等。按驱动形式分自动阀门:靠介质本身的能力而动作。驱动阀门:包括手动、电动、气动、液动等按压力分真空阀:小于标准大气压低压阀门:PN≤1.6MPa中压阀门:PN2.5~6.4MPa高压阀门:PN10.0~80.0MPa超高压阀门:PN≥100Mpa按工作温度分超低温阀:t<100°C低温阀:-100°C≤t≤-40°C常温阀:-40°C

提供各类阀门型号大全,各类阀门型号大全文库会员下载,编号:1700742578,格式为 docx,文件大小为16页,请使用软件:wps,office word 进行编辑,PPT模板中文字,图片,动画效果均可修改,PPT模板下载后图片无水印,更多精品PPT素材下载尽在某某PPT网。所有作品均是用户自行上传分享并拥有版权或使用权,仅供网友学习交流,未经上传用户书面授权,请勿作他用。若您的权利被侵害,请联系963098962@qq.com进行删除处理。

下载

下载 下载

下载 下载

下载 下载

下载 下载

下载 下载

下载 下载

下载 下载

下载 下载

下载 下载

下载 下载

下载 下载

下载